In most simulations, air and the pressure it exerts is not taken into account. There are situations thinkable, however, in which air plays an important mechanical role. An air gun is an example of this: compressed air exerts a force on a projectile, causing it to be propelled. In this blog, I will show how to model air using CEL, using a chamber in which air is compressed with a plug resting on it as an example.

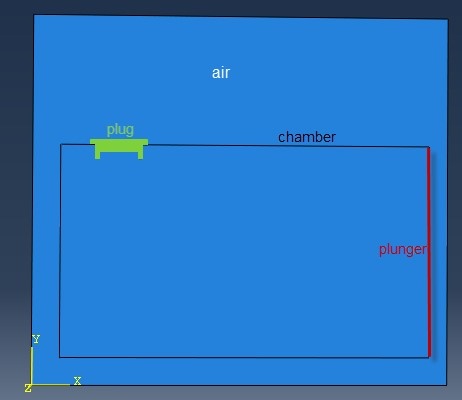

Geometry

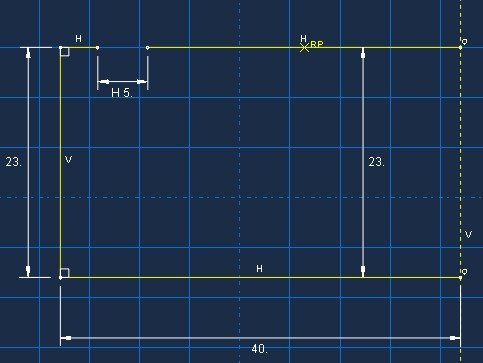

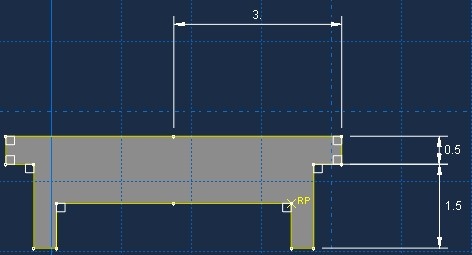

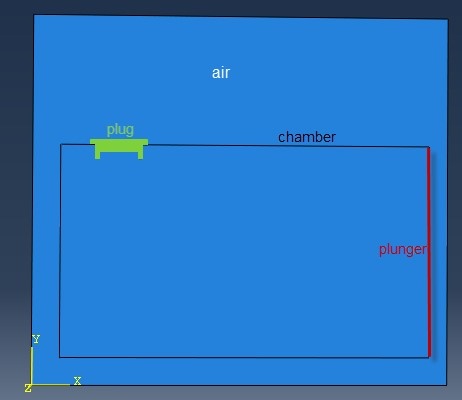

For this simulation, 4 parts are created: a part for the air, a part for the chamber that contains the air, a part for the plunger that will compress the air and a part for the plug. For simplicity, a thin slice instead of a full 3D model is used.

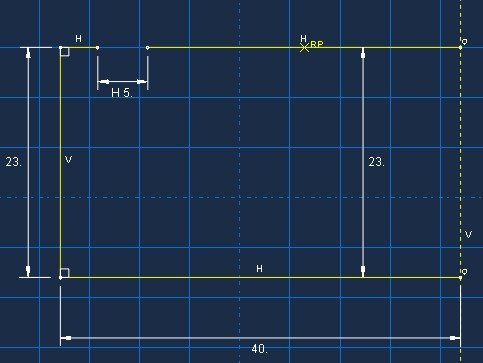

The chamber and plunger are modelled with discrete rigid parts. They are sketched and extruded. The geometry of chamber is shown in the image. The plunger is simply modeled as a plate that precisely fits into the chamber.

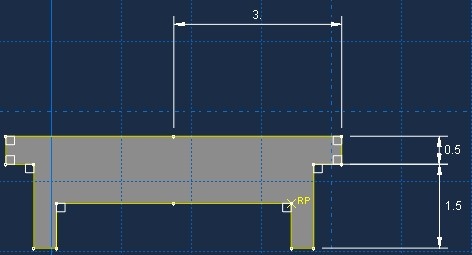

The plug is modelled as an extruded body, with aluminum material properties. A rigid body constraint is applied to it. This allows the inertial properties to be calculated automatically.

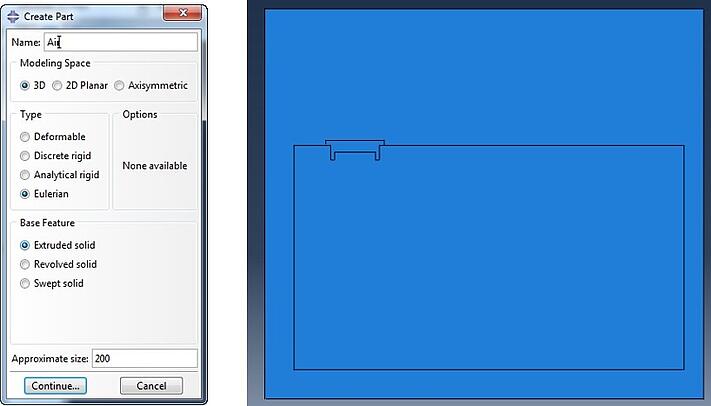

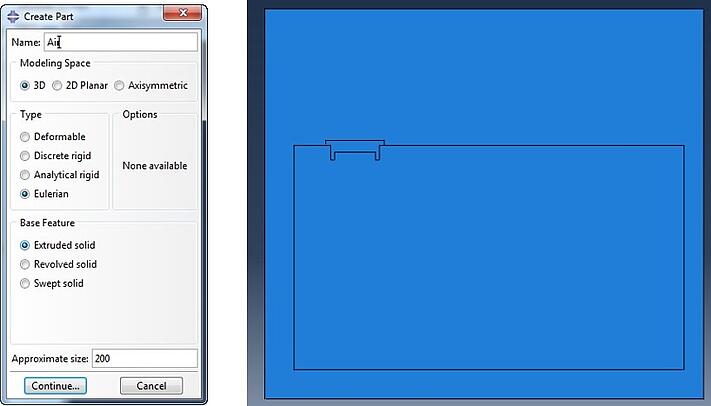

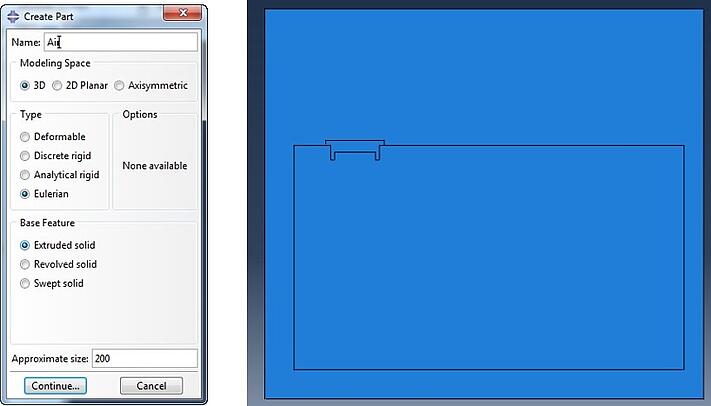

An Eulerian part is used to model the air. It is clearly bigger than the chamber on all sides, especially on the top to show the popping off of the plug.

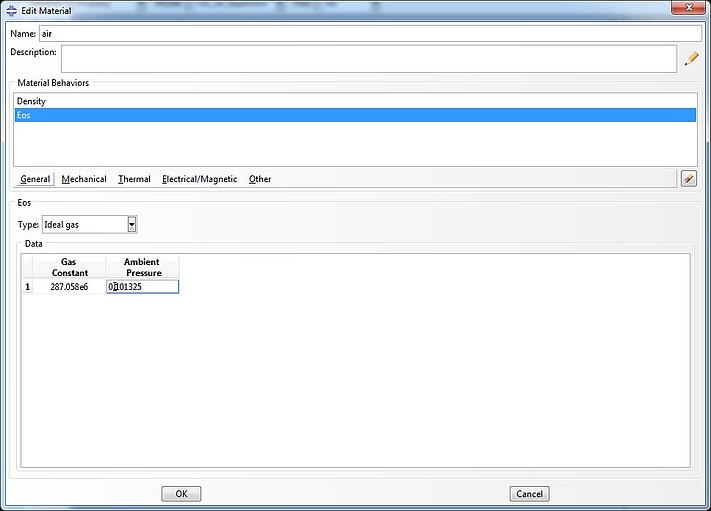

Material

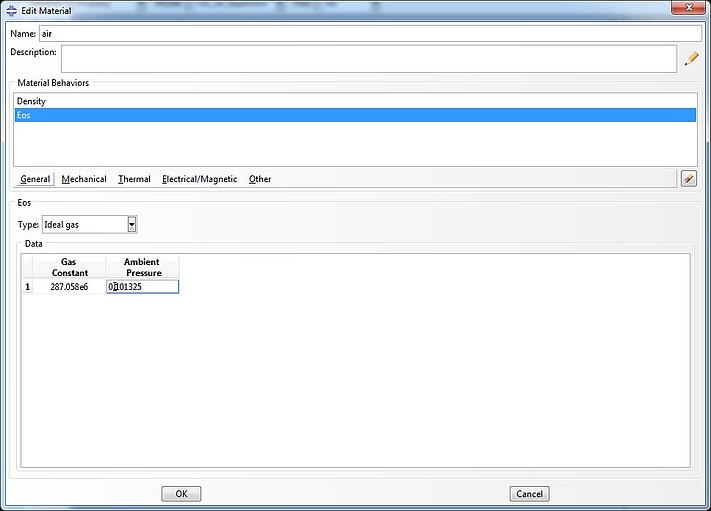

The air is modelled with an equation of state of type ‘ideal gas’. The specific gas constant (287.058e6 mJ/(tonne K)) and ambient pressure (0.101325 MPa) must be specified. In the output, a pressure of zero will correspond to this ambient pressure.

The density of the air (1.225 e-12 tonne/mm^3) and specific heat (Cv = 7.18 e8 mJ/(tonne K)) are also specified. While this defines the material properties, it does not define the initial state of the material. To specify the initial state either the initial pressure stress or the initial temperature must be defined. Along with the density (as provided in the material properties) this defines the initial state. Alternatively, both initial pressure and initial temperature can be defined. In this case, the user-defined density is replaced by a density that is calculated based on the specified pressure and temperature. In the current example, an initial pressure of 0 (corresponding to the ambient pressure) will be prescribed throughout the model, as explained in the section on specifying initial gas pressure.

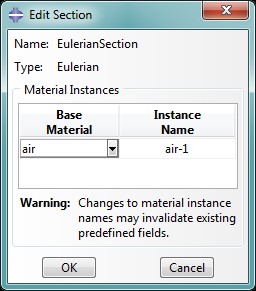

Section

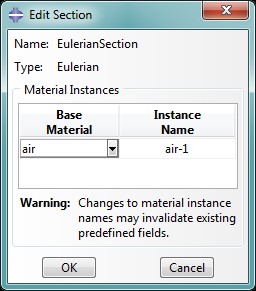

An Eulerian section is created for the Eulerian part and assigned to it. This does not create air material yet; by assigning the section only the possibility of having Eulerian material in the specified region is defined.

A material assignment will be used later on to define the location of the material.

Assembly, Steps & Output

All parts are instanced into the assembly in their appropriate position.

An explicit step lasting 1.5 ms is created. For the output, it is important to request volume-averaged values for the Eulerian part. In this case the volume-averaged stress components and invariants (SVAVG) are requested, besides displacements.

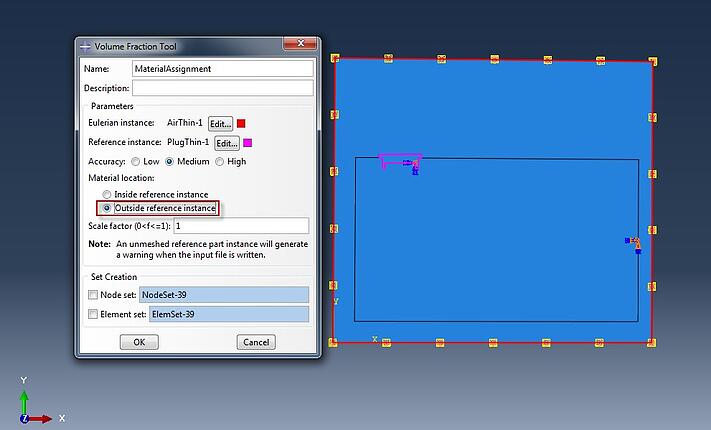

Material Assignment

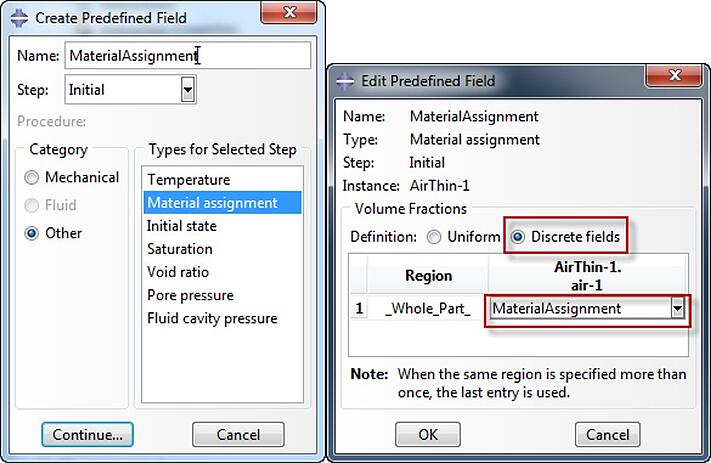

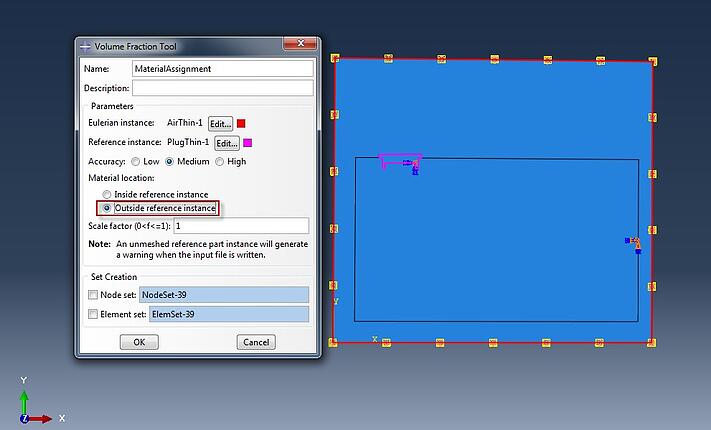

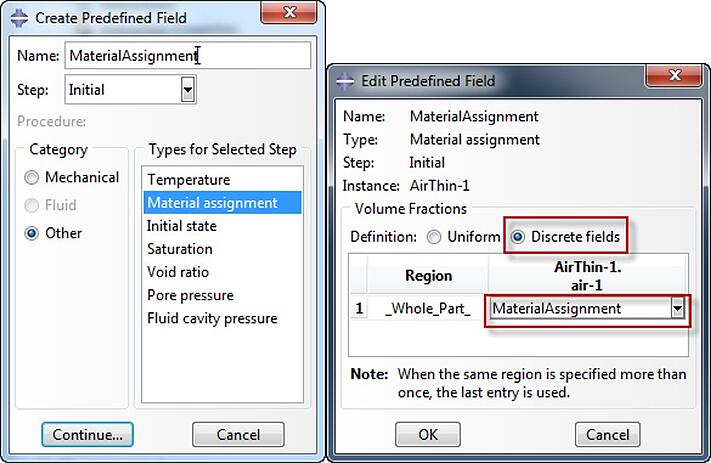

For the material assignment, two things are done. First, a discrete field is created to define where the material should be located, and then the material assignment itself is defined.

The discrete field can easily be made using the Volume Fraction Tool, available in the Load and Interaction modules, via Toolsàdiscrete fieldàvolume fraction tool. A meshed Eulerian instance must first be specified (in this case the ‘air’ part) and then a reference instance (in this case the plug). It is then possible to specify whether the material should be inside or outside the reference instance. In this case, the material is specified to be outside the reference instance. By selecting ok, Abaqus calculates a discrete field with volume fractions for the Eulerian instance. In this case, the air is then everywhere, both inside and outside the chamber, except for the region where the plug is located. If the edges of the reference instance pass through elements of the Eulerian instance, these elements will be partially filled.

The discrete field created this way can be used in the material assignment definition. A predefined field of type material assignment must be created, selecting the air part as the Eulerian part instance. For the definition ‘Discrete fields’ is chosen, and the previously created discrete field is selected.

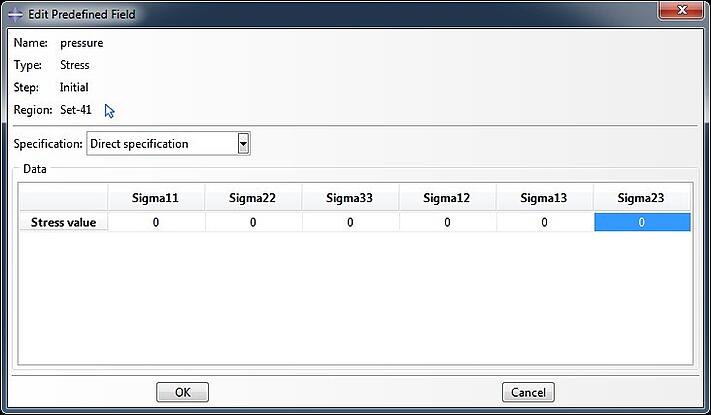

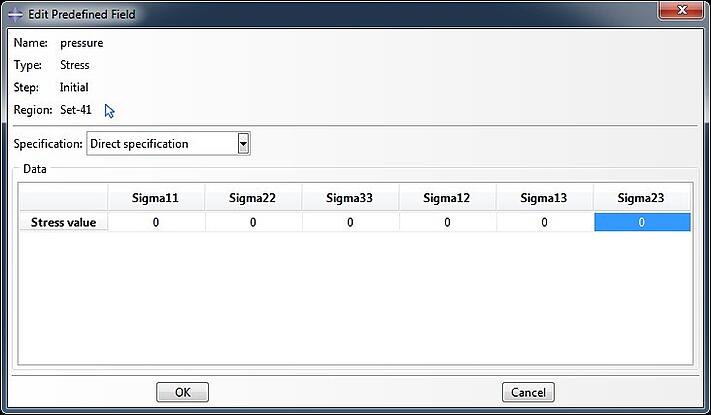

Specifying Gas Initial Pressure

The initial gas pressure, required to specify the initial state of the gas, is specified by creating a predefined field in the initial step of category mechanical and type stress. A value of 0 for each stress component, so initially the gas pressure equals the ambient pressure.

Loads, Boundary Conditions & Contact

Displacement is prescribed to the plunger using a smooth step amplitude, so the plunger will gradually increase speed to compress the air. The chamber is fixed completely. Displacement and rotation of the plug is restricted, so it can only move in the xy-plane. No outflow of air in z-direction is allowed on the top and bottom planes of the simulated slice using a velocity boundary condition. A gravity loading is applied to the model. General contact with default interaction properties is used.

Results

In the simulation, the pressure inside the chamber increases as the plunger moves forward causing the plug to pop off as can be seen in the video below.

Want to Learn More About Abaqus?

Join for one of our free workshops.

Register Now