In these days, everything is about innovation and a better position and marketshare then your competition. So if you work for a company which develops and produces their own products, the question raises; how do you develop an outstanding product which differentiates from competition on performance, quality, serviceability and life?

Just applying what is in your typical standards, regulations and norms, probably doesn’t provide you with the most lean and mean differentiator. Besides that, most codes and norms describe a well-defined and safe set of development regulations for your typical products or services, but they don’t give you a lot of flexibility regarding development freedom and possibilities to reduce the “overweight” associated with safety factors or really develop for the best performance. On top of that, most codes and regulations such as ASME, DNV-GL, Lloyds and many others are quite conservative and typically describe a linear way of calculating.

Before diving into more detail about linear analysis and the disadvantages of doing such, I do understand that a code or norm is something historically, but personally I would not favour the lack of flexibility of adopting new available techniques in those codes and norms. Luckily we see some small changes and codes do accept non-linear analysis more and more to get your products validated.

Most of the structural engineers will confirm that linear finite element analysis provides answers with higher stress values and thus, products will be over defined and over engineered based on the incorrect (linear) assumptions.

These generic assumptions for Linear Finite Element Analysis are the following:

- Materials are being treated as linear

- Forces are being applied slowly and don’t change direction in time

- Contact doesn’t change in time

- Deformations of the product are small

Let me handle these assumptions one by one.

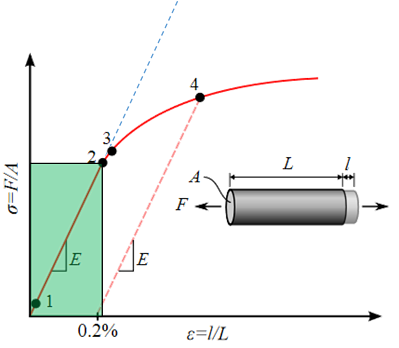

Assumption to Treat Material As Linear

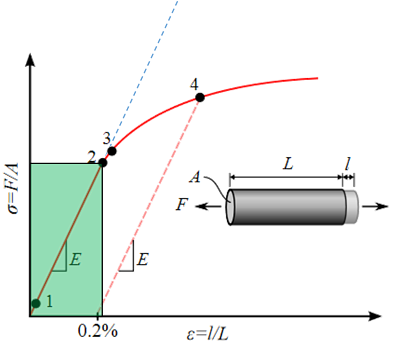

If you treat materials as linear, your research will be limited to a certain subset of materials in which there is a certain linear behaviour, such as steel. Now if during one of your simulations, you would find a stress value which is higher than the yield point, your linear solver will just continue linearly (as the blue dashed line) and therefore create inaccurate high-stress results. See picture below.

In the situation where the stress is beyond the yield stress value(2), you should define plasticity in the material model and investigate if any failure will be likely. This is what you would do in a Non-Linear Analysis. The Linear Analysis only acts in the green area of the picture below.

For other types of materials such as plastics, rubbers, etc., these initially don’t even show a linear behaviour in many cases. So there is no actual yield point and therefore you will end up with inaccurate results when only using an E-modulus and Poisson Ration in a Linear Analysis.

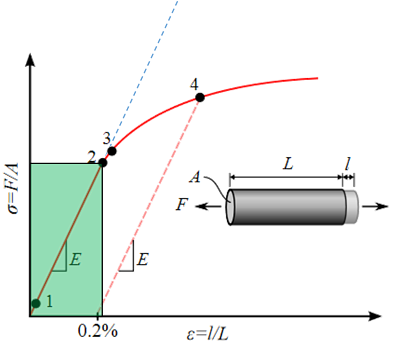

Assumption to Apply Forces Slowly and Keep Their Initial Direction

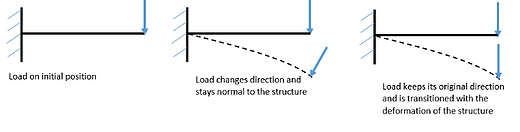

Linear analysis assume that your forces are applied slowly and don’t change direction in time. Especially this last one is rather important, so if you place a load on a structure, and the structure would deform, you would expect the force to change its direction normal to the surface to which it has been applied (just like the middle picture below). This is not the case for Linear Analysis. Normally the load is being transferred to the end point, but keeps its initial direction (like the most right picture below). This assumption can provide you with inaccurate results as well, unless you would be applying a gravity load.

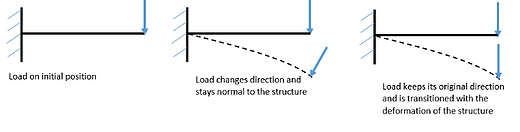

Assumption to Not Let Contact Change in Time

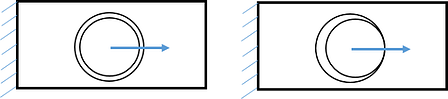

Linear Analysis assume that the contact doesn’t change in time. So when you model your 3DCAD geometry ready for production, you probably take into account some tolerances. Most Linear Analysis do seem to provide you with an answer, but this answer is quite likely to be inaccurate as well. You could change your design on such way that for FEA purposes there is no gap in the design anymore, or in a more accurate approach, you could just run a Non-Linear Analysis. See pictures below.

Assumption to Have Small Deformations

The last assumption for Linear Analysis is that the deformations of the endresult should be small. The reason for this is a combination of the force that keeps it’s initial direction, but also the structure itself changes in stiffness if you deform it largely. Think of a paperclip which you bend significantly, and then trying to bend it back to it’s original position. Because of the permanent deformation and the kinematic hardening, the structure has become stiffer than initially. Another good example is sheetmetal. If you bend sheetmetal, you apply permanent deformation to it, and most of you understand that the structure has become stiffer because of that. So if you perform a Linear Analysis which assume that there is no kinematic hardening, or no permanent deformation, the endresult of you Linear Analysis is way off and much more flexible than it is in practice. In order to calculate this accurately, you should perform a Non-Linear Analysis and take into account the residual stresses and kinematic hardening effect from the actual bending process which by the way, you can simulate as well.

So What Is the Takeaway From This?

If you would jump into the world of Non-Linear Analysis, you will discover that a lot of your current designs and products are designed based on inaccurate assumptions. This brings a huge potential for businesses to develop more outstanding products which differentiate from competition on performance, quality, serviceability and life. The only thing you need to do is to step out of you comfortable Linear zone and try using new Non-Linear techniques which bring you closer to best product performance. Of course we can help you with you leap jump, which isn’t such a big jump anyway. Find out more on how to perform Non-Linear Analysis?