On Friday the 26th or October, Simuleon and Elastomer Research Testing (ERT) are hosting the free hands-on workshop ‘From testing to Finite Element Analysis for Rubbers with Abaqus’. In this unique co-hosted event Simuleon will present their solutions based on the SIMULIA portfolio and ERT will present their Rubber testing capabilities to gain material specifications for usage with SIMULIA Abaqus FEA.

On Friday the 26th or October, Simuleon and Elastomer Research Testing (ERT) are hosting the free hands-on workshop ‘From testing to Finite Element Analysis for Rubbers with Abaqus’. In this unique co-hosted event Simuleon will present their solutions based on the SIMULIA portfolio and ERT will present their Rubber testing capabilities to gain material specifications for usage with SIMULIA Abaqus FEA. Starting with a lecture session covering the essential concepts of advanced simulation for Rubbers, the course also gives the attendees the opportunity with our hands-on workshop, to model advanced phenomena such as non-linear elastic behaviour & material calibration, in-compressibility, element selection, shrink-fit & pressure penetration and other highly complex events with SIMULIA Abaqus.

What topics are discussed?

Rubbers are seen more and more often in daily life. Applications range from packaging and consumer goods to more sophisticated scenarios like the medical industry or even vibration damping parts in the automotive industry. Whatever the application or the industry, it is very important to have an accurate material model that captures all the necessary behaviour that we want to evaluate to determine whether the product fulfils the necessary requirements. Moreover, the way multiphase materials are manufactured has a very dominant effect on local stiffness and strains in the part and needs to be accounted for in the structural model.

Our first presentation “Introduction to Rubber” gives an overview of possible complex behaviours to be considered for Rubber.

The second presentation “Theoretical background of non-linear Analysis“ will give you insights in the possibilities, assumptions and techniques used within non-linear analysis.

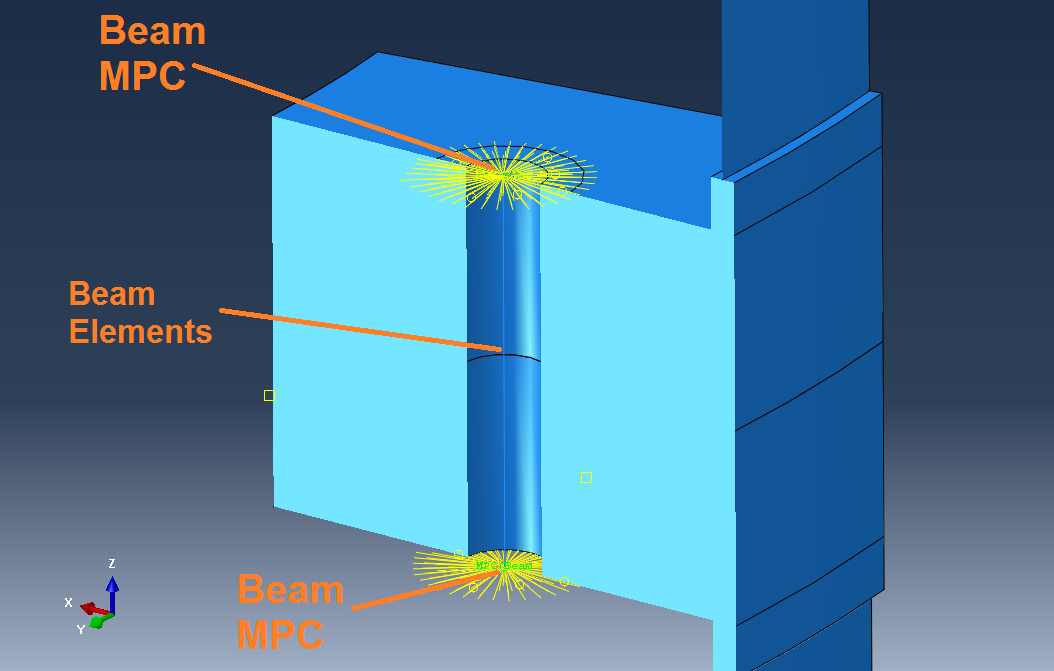

The hand-on session, teaches you how to perform non-linear analysis for rubber, by handling tutorials about large deformation, material calibration, pressure penetration, shrink-fit, fender / cushion inflation and impact absorption, which you will simulate with SIMULIA Abaqus software yourself under guidance of our Abaqus Application Engineers.

08:45 – 09:00 – Welcome and coffee

09:00 – 09:30 – Introduction Simuleon

09:15 – 09:30 – Introduction ERT

09:30 – 10:45 – Introduction to Rubber and Material Testing (ERT)

10:45– 11:00 – Coffeebreak

11:00 – 11:15 – Introduction to Abaqus/CAE

11:15 – 11:45 – Hyperelastic material models and calibration in Abaqus

11:45 – 12:30 – Hands-on session I – Material Calibration

12:30 – 13:15 – Lunch

13:15 – 13:45 – Practical rubber modeling – Element type etc.

13:45 – 14:15 – Applications – Pressure penetration, Shrink fit, etc

14:15 – 14:30 – Coffeebreak

14:30 – 17:00 – Hands-on session II – Fender / Cushion Inflation, Impact Absorber, Pressure penetration, Shrink fit

Join us and register for this free hands-on workshop on the 26th of October.

Limited seats available (12) for people coming from BENELUX only.

More Information & Registration