As you may have noticed, we're working on kind of a series of blogs on the simulation of different production techniques. This time, we will look at roll forming.

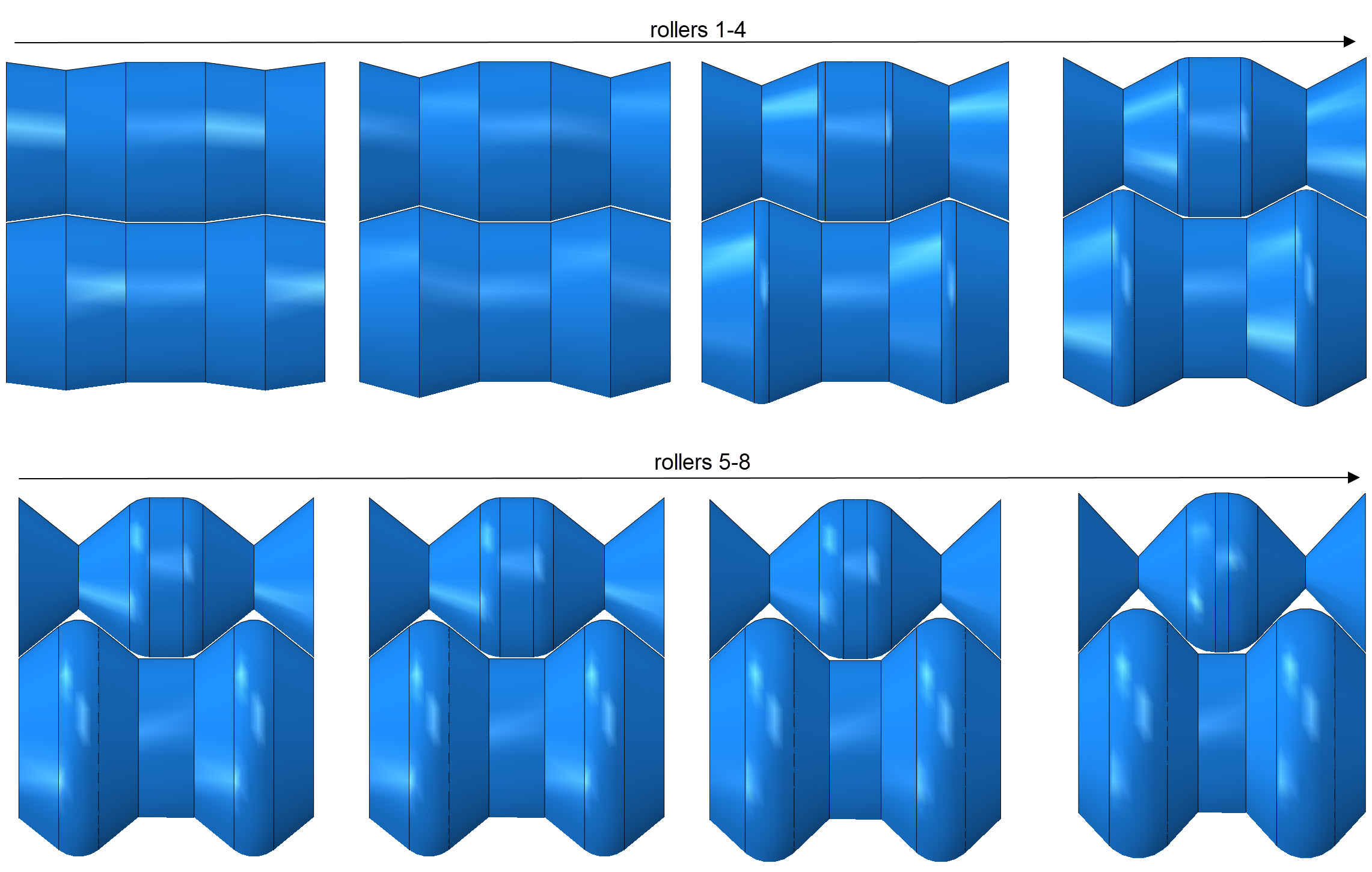

During the roll forming process, a long strip of sheet metal is continuously bent into the desired cross-section. The strip passes through a number of sets of rollers, where each set performs a part of the total desired bend, until the final profile is obtained.

In this example, we'll simulate the forming of a profile for a road guardrail.

Figure 1: Example of the type of product being simulated.

Geometry

The sheet metal is modelled as a shell. It is a flat strip that is 3.2 m long, 40 cm wide and 1.5 mm thick.

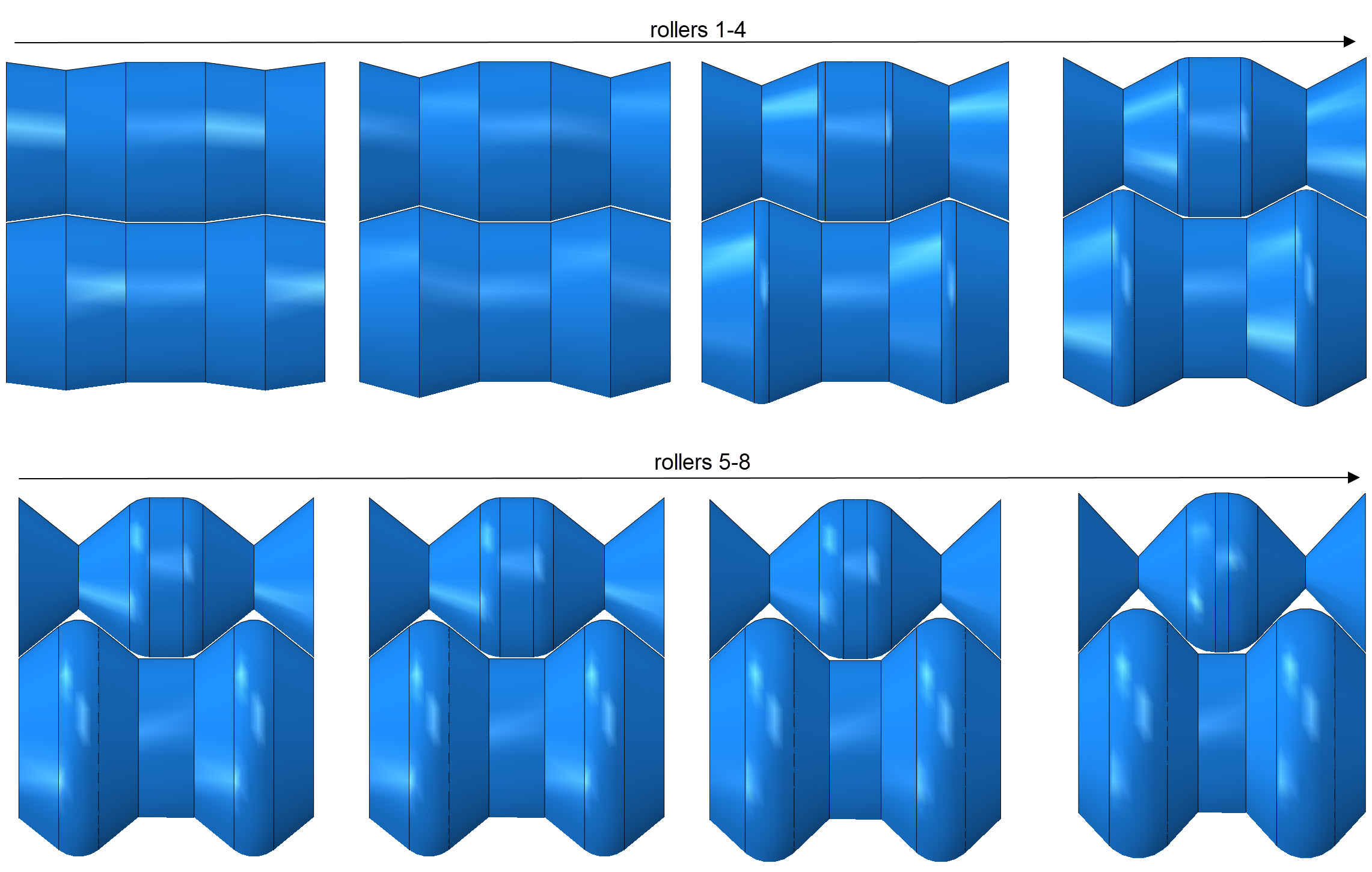

Eight sets of rollers are used to shape the material. They gradually change shape, to make the profile increasingly more pronounced.The rollers have a grap between them, with a width of 2 mm.

Figure 2: Sets of rolls used to shape the material.

Material

Elastic-plastic stainless steel material properties are used for the sheet metal. The rolls are considered rigid. They have inertial properties corresponding to steel.

Model Set-up

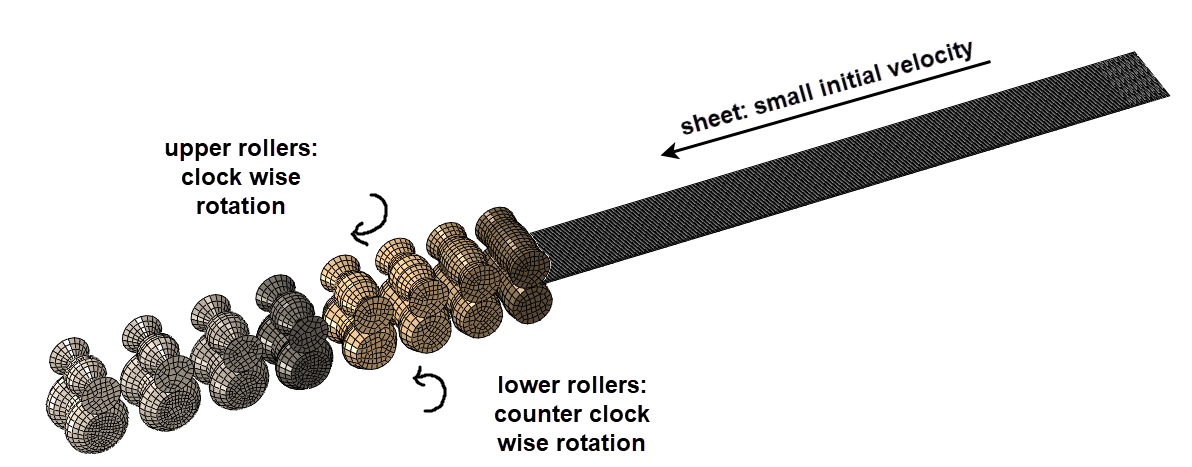

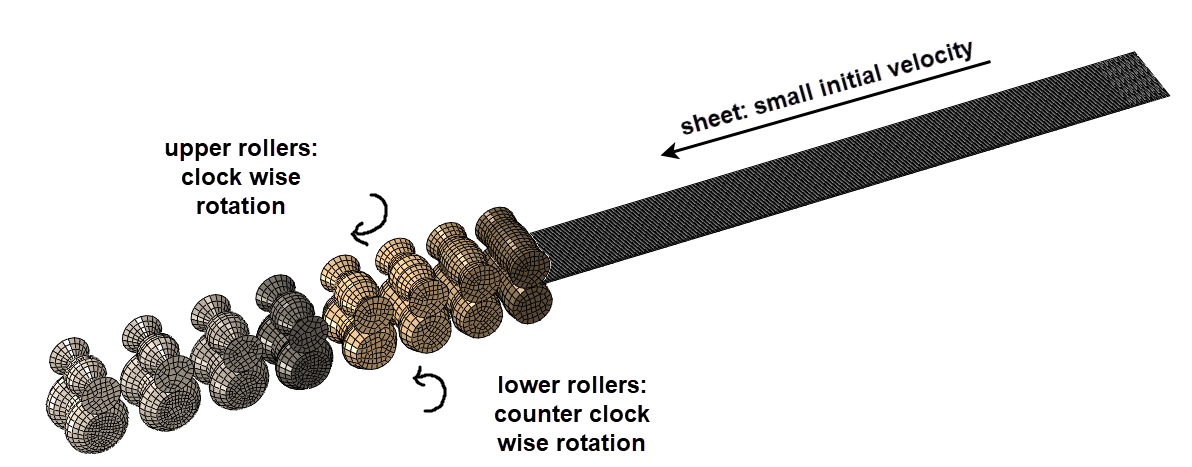

The motion of the rollers is prescribed in this analysis: they rotate around their axis with a specifed angular velocity without translational movement. Contact is included with a friction coefficient of 0.1. No loads or boundary conditions are applied to the sheet metal.

A small initial velocity is prescribed to the sheet metal, to bring it into position. Once the sheet metal is in contact with the rotating rollers, it will be pushed forward by them and it's deformation is determined by the contact with the rollers.

Figure 3: Model set-up.

Abaqus/Explicit is used for this analysis. The step time was one second.

Results

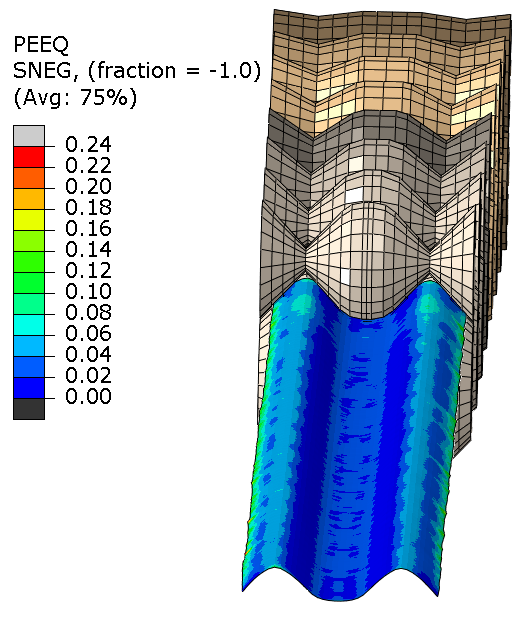

The sheet metal passes through all the rollers and obtains its final shape.

Video 1: The roll forming process

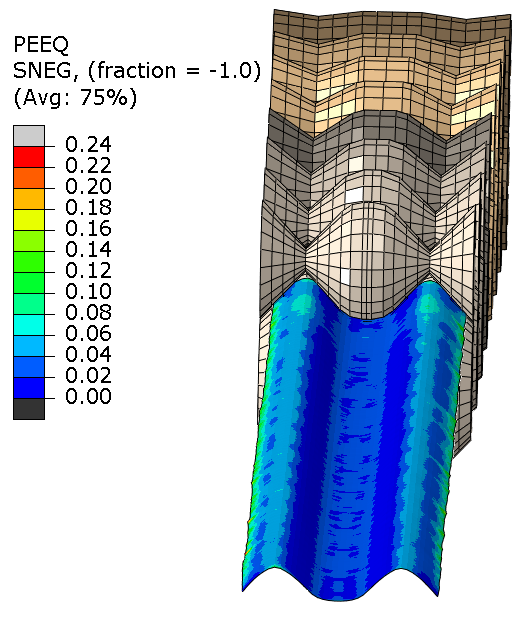

Figure 4: Final shape of the steel, colored based on plastic strain.

Apart from the deformed shape, other outputs such as the force on the rollers, contact pressures and stress in the sheet are available as well.

Discussion

The final shape can be compared to the designed shape, to determine whether it is within the tolerances allowed. In this analysis, the sheet becomes slightly off-center, leading to a somewhat asymmetric result. There is also a bit of wrinkling on the edges of the product. These effects are probably unwanted and may require further research.

A model like this, can be used to determine the influence of various aspects of the set-up, by varying them. Such aspects could include:

- the distance between the rollers. Currently this was 2 mm for a sheet thickness of 1.5 mm. If this is reduced, then the material will have less space, and ultimately it will be compressed as well as bent.

- tension on the sheet metal. Currently no tension was applied to the sheet metal, so that the rolls would determine the movement of the sheet. In practice, it will be connected to more sheet metal on both sides, that may push and pull on it.

- size/shape of the rollers. These can be optimized to obtain the shape of interest with the smallest possible amount of rollers.

- friction. Currently a friction coefficient of 0.1 was applied. Friction, especially in combination with tension on the sheet metal, can influence the results

- (mis)alignment. Misalignments may lead to asymmetric results and other unwanted effects.

- speed. A too high speed may lead to unwanted dynamic effects, while a too low speed may not be cost-effective.

Conclusion

Abaqus can be used to simulate the roll forming process to determine the deformed shape, among other outputs. An analysis like this can be used as a starting point for further investigation into the influence of various aspects on the roll forming setup.