One thing that has amazed me in the later part of my simulation career is how organizations can spend big on simulation technology, whilst completely neglecting the importance of material data, its management, and ultimately its commercial exploitation.

I think we often forget, or maybe often underplay, the importance of material definitions and understanding in our simulation workflows. Often, and historically I’ve been guilty as charged on this point, we ship out responsibility for understanding the material to a third party and engineer the situation to make it somebody else’s problem.

Years ago, I decided that hyperelastic materials were too difficult to understand, so I’d get somebody else to do the testing, and as a bonus if I chose the right people, they would tell me what to put into Abaqus. And to complete a couple of relatively simple projects that was more than adequate. But in the intervening years, there has been a subtle shift in expectations.

Historically, getting a model to work was often enough to provide useful insights into design improvement. But as simulation technologies become more mature and mainstream, enough for Abaqus to have become a CAD integrated design tool, our expectations of insight and understanding, and critically, how they contribute to improved design performance across the board, have become heightened. As I’ve said before in blogs, correlation is IP in the simulation world. And correlation needs an indepth understanding of materials science. If you want to own the IP. you can’t outsource the understanding (which is perhaps stating the obvious). So I’d painted myself into a corner and the only way out was to raise my material modeling game.

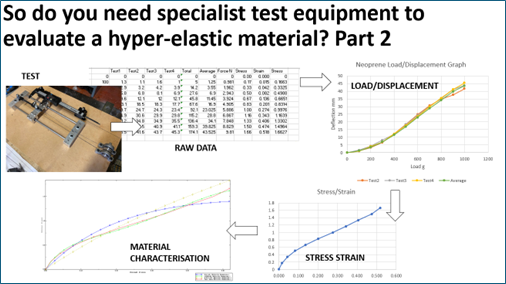

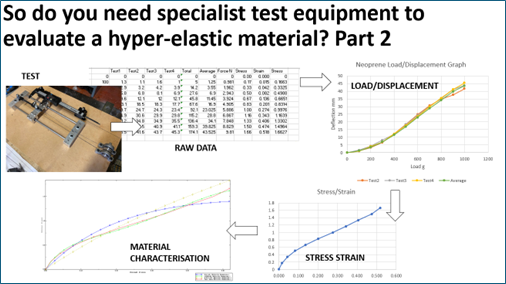

I don’t want this to look like “Mythbusters” or, for the older demographic, “The Great Egg Race," but to cut a long story short, I designed and made a test rig to measure the properties of elastomers. In my garage (which contains a lathe, milling machine, and 3D printer). I used this new end-to-end, rig-to-results, approach to build my understanding of hyperelastic materials and how you model them. I’m still no Randy Marlow, but from the end-to-end approach I’ve now adopted, I’ve built a deeper understanding of the materials and how they are represented in my finite element models. I’ve created IP. And for somebody working on their own with everything in spreadsheets and PPTs, that’s fine.

But what about a proper enterprise? Exploitation is really only possible with dissemination and critically, management (who knew management was important?).

But the traditional analyst’s viewpoint is often that anything approaching management, and particularly data management, looks like an overhead at best. We’ve all heard stories about the simulation departments of big corporates subverting PLM implementations to streamline their own processes. But material characterisation, management and dissemination of the material IP is genuinely something that provides a real benefit, and frankly, this works best within a corporate PLM implementation.

The 3DEXPERIENCE Platform Material Calibration app genuinely moves the simulation world forwards. Apart from taking the material calibration capabilities found inside the analysts favourite interface (Abaqus/CAE) and moving them forward to expand and enhance the core process, being integrated into the 3DEXPERIENCE Platform allows this enhanced materials IP to be disseminated across the enterprise, and exploited inside all simulations, because these simulations are part of the same managed environment.

So that’s enough of the why. Let’s look at the technology. In some respects, the 3DEXPERIENCE Material Calibration App is exactly what it says on the tin. And given the context within which this blog is posted, I’m going to assume that everyone who reads this knows what the 3DEXPERIENCE Platform is. I’m certainly not going to get into explanations of PLM platforms here.

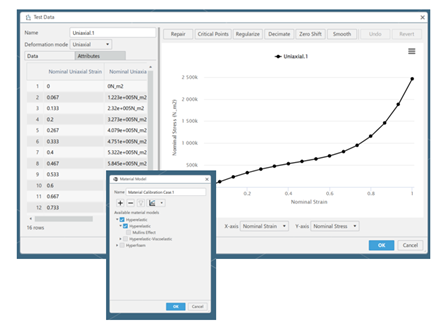

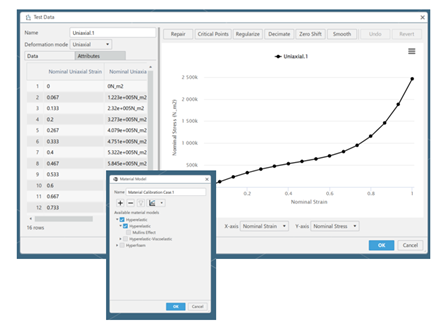

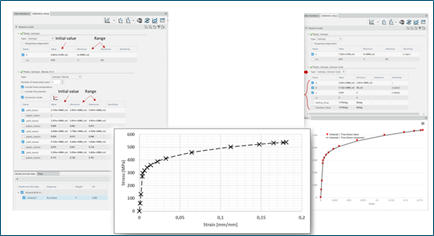

The Material Calibration App is intrinsically a part the 3DEXPERIENCE environment. Which is how it achieves the management and dissemination part of its function. But we’ll come to that later. Firstly, we’ll look at replicating the established hyperelastic material calibrations that many of us know and love from Abaqus/CAE, because the workflows aren’t completely new, it’s the scope and environment that are new.

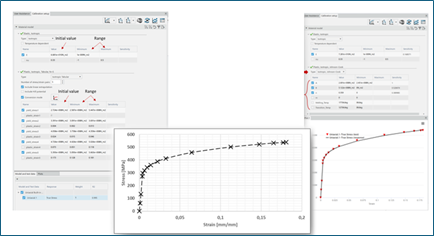

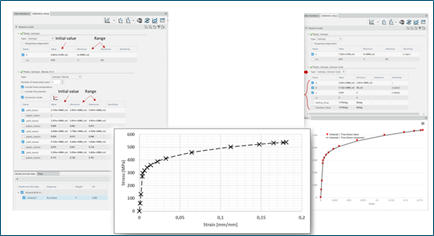

We can read test data and evaluate material modelling options. And for very good reasons that’s an established workflow. The app makes life in the real world a lot easier with functions that essentially let us clean up the test data, shift zeros, reducing the number of data points and smoothing. All issues relevant to my own test data.

Once we’ve done that, we can evaluate material model options in the way I talked about in the webinar I wrote about my new interest in hyperelastic material behaviours.

But the key feature here, and one that isn’t particularly graphically interesting, but is IP critical, is the ability to make the model available to all users in the organisation, and also to lock it into the audit trail necessary if analyses are used to prove fitness for critical purpose. That should be enough for the board to justify any expenditure in this direction, but probably isn’t sufficient to get the specialist simulation engineer to look up from his (or her) copy of Zienkewicz. For that we need to unlock some simulation potential.

One area where this potential is obvious is the ability to look at calibrating materials beyond hyperelastics. In fact, the list of material models that the app can investigate is seriously extensive. Making a list here probably isn’t that useful – if you want to have a look the documentation is pretty extensive, but suffice to say the options range from linear elastic, to the parallel rheological framework, through hyperfoams, nitinol and the students favourite, Johnson-Cook. But that’s a list of features, not benefits. The benefit, which may not be entirely obvious, is that you have a structure for material model development, and that structure makes investigation more straight forwards and productive. I may well have overworked the point that these investigations are indistinguishable from product development.

A blog probably isn’t the best format for an in depth look at underlying technologies; which approaches are applicable and how they can be employed is almost certainly dealt with better in a webinar or real life face to face meeting. Because these change from application to application, engineer to engineer. But if we look backwards, and think about the days of paper documentation, we can see what we’ve got. We’ve always had numerous material modelling options, they were in a book. But to actually use and evaluate them, and develop their application you essentially had to create your own framework on a case by case basis. Or simply hack around the model space until things started to work. Or didn’t. By creating a framework around existing and developing modelling technologies the barriers to investigating additional complexity and scope are significantly reduced. And by incorporating the process into a managed environment, we record and exploit the new IP as the workflow development unfolds. And that should grab the attention of the most committed simulation engineer.

For more information or to get a quote: